Solina Health is involved in developing and implementing a mechanism for strengthening the vaccine Supply Chain Management (SCM) in Nigeria.

Introduction

Strengthening Nigeria’s Vaccine Supply Chain project is funded through the basket fund con- tributed by the Government of Kano State, Dangote Foundation and Bill and Melinda Gates Foundation for the redesign of Nigeria’s vaccines supply chain in Partnership with McKinsey and Company, Clinton Health Ac- cess Initiative and National Primary Health Care Development Agency (NPHCDA) The project kicked off in April 2013 and is cur- rently being implemented in Kano state with the aim to provide a sustainable long term impact targeted at improving the immunization coverage rates in the state from 38% in 2012 to 80% in 2015 .

Key Challenges

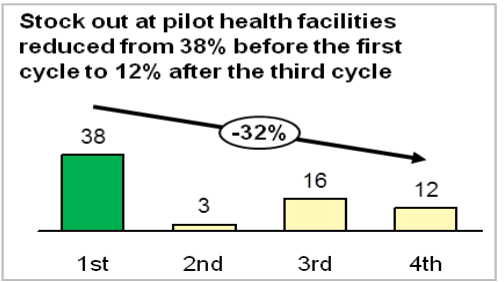

Stock levels were below acceptable levels. 90% of the time, there was frequent stock outs of vac- cines at the LGA and the facilities resulting in low coverage rates.

Most of the cold store were not functional and dilapidated. Inadequate/inconsistent funding for logistics/ transportation making the supply of vaccines across facilities very difficult.

Poor Data Collection and usage.

Inefficient vaccine distribution system were driv- ing low coverage rates and threatening Child health.

Implementation Strategies

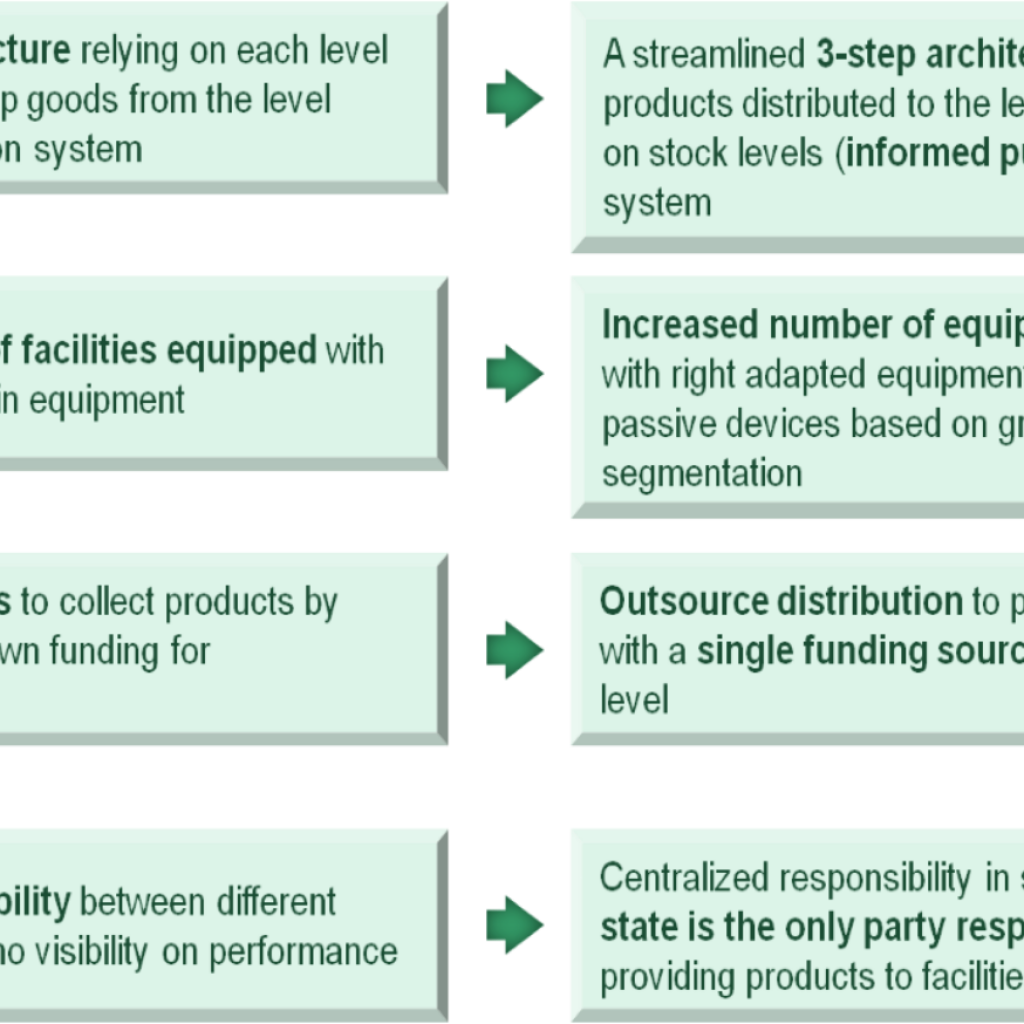

Solina health was engaged to develop and implement a supply chain strengthening initiative. We conducted an analysis of the system, which revealed several areas of implementation to improve vaccine supply:

Improving visibility of stock: We developed a dashboard to track stock.

Improving allocation of vaccine stock: We used data-driven advocacy to increase allocations.

Implement quick fixes in the supply chain management which includes activation and revamping of state cold store, provision of inventory management system at the LGA and training of key cold chain officers on vaccine Supply Chain Management.

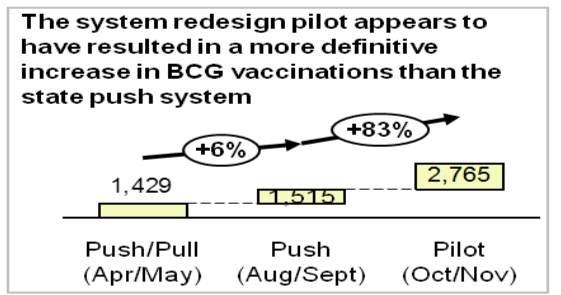

Pilot of system redesign: We have successfully conducted a pilot of the system redesign in18 facilities across 10 LGAs in the state.

Impact

The redesign of vaccine logistics has effectively transformed the routine immunization landscape in the following ways:

Inadequate stock has decreased from more than 50% at any one time to less than 2%.

A sustainable process is in place to service cold chain equipments.

The number of children vaccinated has increased by 20-60% for RI antigens.

There is complete and transparent inventory of supplies at the facility.